Description

High Capacity Inline Strainers are Perfect for Higher Operating Pressures

Today’s processing pipe lines require strainers with an increased capacity to meet production needs of state-of-the-art Food, Beverage and Pharmaceutical manufacturing facilities.

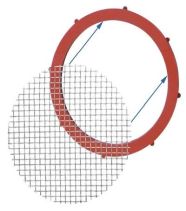

Rubber Fab’s sanitary strainers protect valuable processing equipment (pumps, spray nozzles, needle valves, heat exchangers and homogenizers) and have been specifically designed to meet the most stringent process requirements. Our sanitary strainer products are manufactured using 316L stainless steel and are designed for maximum installation flexibility, sanitary construction, and unrestricted flow.

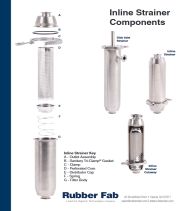

Rubber Fab’s Hi Capacity sanitary strainers feature a machined neck line, instead of a spun neckline; a design improvement that allows higher operating pressures, greater product out! Our Hi Capacity strainers also provide triple the effective filter area as standard Inline and Side Inlet units; increasing run time, and reducing costly down-time.

Rubber Fab’s Inline and Side Inlet sanitary strainers are available in single length and double length models, both providing cost effective filtration. Rubber Fab’s strainer housing accepts a wide range of re-usable strainer elements, wire mesh overscreens, sks overscreens, wedge wire and disposable filter socks. Rubber Fab’s Side Inlet sanitary strainers use the same wire mesh overscreens and filter socks as the Inline units. The Side Inlet, however, is specially designed to accommodate piping configurations using a side inlet.

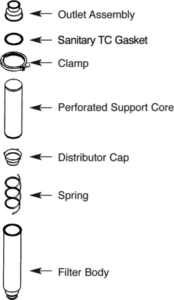

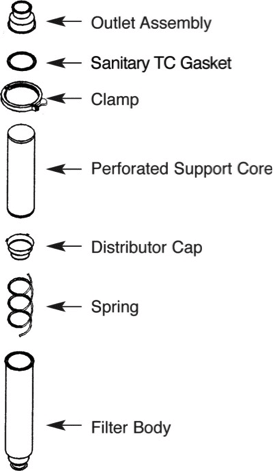

Rubber Fab’s wire Mesh basket liners are continuously resistance spot welded inside the perforated support basket, providing a snag free seam. When in use the mesh lined perforated basket strainer seats on a machined neckline inside the housing and the strainer bucket’s handle rests against the underside of the top cover. This design ensures that product cannot bypass the mesh lined strainer basket.